We look at the 'total cost' of a custom superabrasive grinding wheel from CDT, and detail the advantages superabrasives have over conventional grinding products. Check it out >

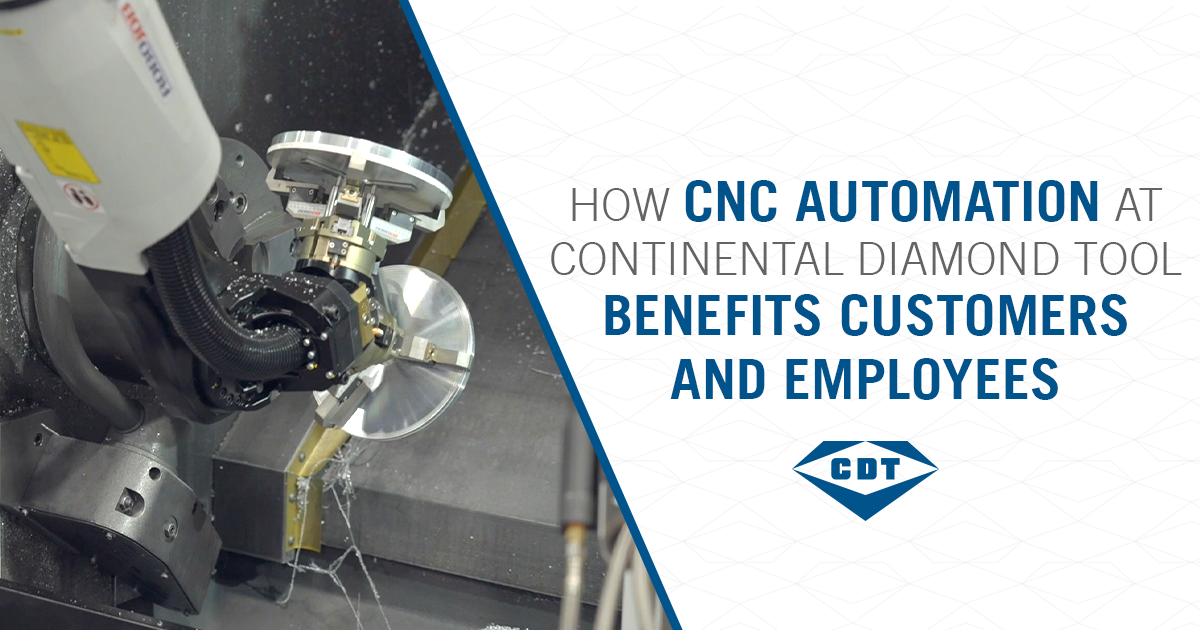

Read MoreWith CDT’s recent investment in CNC automation through robotics, they are seeing benefits to quality, speed, and employee satisfaction. Check out what this new technology means for CDT customers and employees >

Read MoreThough most of our employees work full-time, we have a great group of part-timers who have come out of retirement to join our team. Learn how a part-time job at CDT could benefit you >

Read MoreIf a customer needs it, CDT makes it happen. Check out just how we accomplish this with our custom superabrasive products in our latest blog article >

Read MoreWe wanted to take a moment to let you know that we truly appreciate working with you, and we’re so grateful for the trust you place in us. We wish you a happy Thanksgiving and the very best throughout this holiday season.

Read MoreIf you are a Komets fan looking for a career change at a team-oriented workplace with great benefits, apply now at www.CDTUSA.net/jobs. Go Komets!

Read MoreThe mechanics of producing aircraft to safely transport people in such harsh conditions, however, is particularly challenging. The solution? Plated CBN grinding wheels.

Read MoreAlways striving to stay ahead of the curve in technology, Consort Precision Diamond is excited to announce that thier newly upgraded plating lab is up and running.

Read MoreAt CDT, our Vitrified products generally serve two distinctly different markets, Vitrified CBN and Vitrified Diamond. Learn about what makes a Vitrified wheel and the capabilities Vitrified has.

Read MoreAt CDT, we're always looking ahead. In this video, President Nick Viggiano explains how CDT has continued to provide products reliably for customers despite all the challenges of 2020.

Read MoreContinental Diamond Tool has experienced extensive growth in Three of their most popular product lines, and they are now adding a third shift to their schedule to increase production and continue to fulfill global orders in a competitive timeframe. Apply today >

Read MoreContinental Diamond Tool now offers a new generation plated product available on carbide, aluminum, copper, or steel substrate bodies.

Read MoreWhat is a Vitrified Superabrasive Grinding Wheel and what are the benefits of using one? In this blog, you’ll learn who should switch to Vitrified >

Read MoreContinental Diamond Tool has implemented and maintains a Quality Management System that meets the requirements of ISO 9001:2015, as a manufacturer and distributor of Super Abrasive Grinding Products.

Read MoreIn part 3 of this 3-part blog series, we explore the advantages and limitations of the Vitrified Grinding Wheel in various grinding applications.

Read MoreWe reviewed the materials of the Vitrified Grinding Wheel development in part 1 of this blog series, now we will discuss the bond. Learn more >

Read MoreJordan Donnelly, CDT’s Plating Research and Development Manager, has been named a Master Surface Finisher (MSF).

Read MoreThe vitrified bond grinding wheel first appeared 150 years ago, and continues to become ever more valuable. Learn more about the evolution >

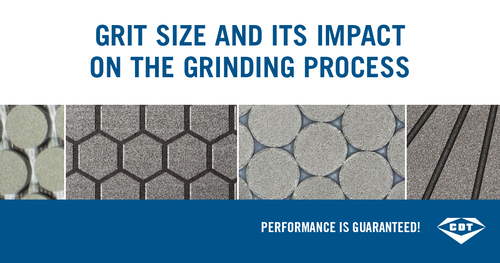

Read MoreGrit size only approximately correlates to surface finish: machine condition and the type of workpiece make a big difference. Learn more >

Read MoreCDT’s grinding lab for research and development will expedite innovation in the grinding industry and reduce costs for customers.

Read More