Continental Diamond Tool has experienced extensive growth in Three of their most popular product lines, and they are now adding a third shift to their schedule to increase production and continue to fulfill global orders in a competitive timeframe. Apply today >

Read MoreContinental Diamond Tool now offers a new generation plated product available on carbide, aluminum, copper, or steel substrate bodies.

Read MoreWhat is a Vitrified Superabrasive Grinding Wheel and what are the benefits of using one? In this blog, you’ll learn who should switch to Vitrified >

Read MoreContinental Diamond Tool has implemented and maintains a Quality Management System that meets the requirements of ISO 9001:2015, as a manufacturer and distributor of Super Abrasive Grinding Products.

Read MoreIn part 3 of this 3-part blog series, we explore the advantages and limitations of the Vitrified Grinding Wheel in various grinding applications.

Read MoreWe reviewed the materials of the Vitrified Grinding Wheel development in part 1 of this blog series, now we will discuss the bond. Learn more >

Read MoreJordan Donnelly, CDT’s Plating Research and Development Manager, has been named a Master Surface Finisher (MSF).

Read MoreThe vitrified bond grinding wheel first appeared 150 years ago, and continues to become ever more valuable. Learn more about the evolution >

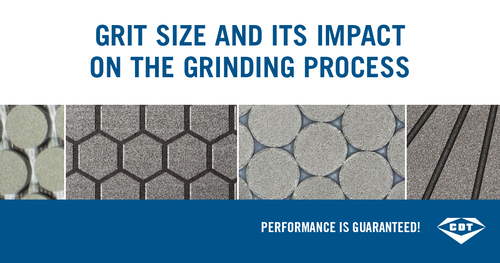

Read MoreGrit size only approximately correlates to surface finish: machine condition and the type of workpiece make a big difference. Learn more >

Read MoreCDT’s grinding lab for research and development will expedite innovation in the grinding industry and reduce costs for customers.

Read MoreQuality and precision are essential in complex, face grinding operations. CDT has fixed abrasive grinding wheels for fine grinding, double-disk grinding, blanchard grinding and more.

Read MoreFind the perfect rotary diamond dresser for your application by considering these 5 factors. Continental Diamond Tool Limited offers decades of expertise and free consultations for customized solutions >

Read MoreIndustry-standard lead times for diamond rolls can take 8 weeks or more. If you are looking for a better, faster rotary diamond dresser alternative, we can expedite service in as little as 4 weeks. Learn how >

Read MoreAre you experiencing these 6 common grinding problems? If so, your grinding wheel may be at fault. Learn more >

Read MoreCustomers report significant improvements to the grinding process and cost savings with CDT’s latest generation of Vitrified Diamond grinding wheels. Learn more »

Read MoreCDT’s Rapid Prototyping Team of engineers were responsible for turning ideas from NASA’s engineers into tools specific for their SpaceX mission. Learn more »

Read MoreContinental Diamond Tool values our partnership and would like to keep you updated as the COVID-19 pandemic continues to evolve.

Read MoreHaving decided to leave conventional grinding wheels in favor of superabrasives, buyers are confronted with a difficult choice between diamond or CBN grit.

Read MoreContinental Diamond Tool Corporation (CDT), an industry leader in Diamond and CBN grinding wheels and tools, today announces their acquisition of Jalsons International Company, a manufacturer and supplier of Stationary Diamond Dressers.

Read MoreEach type of bond, vitrified, resin, metal or plated, has distinct performance characteristics. Learn about the choice between diamond and CBN as it relates to vitrified grinding wheels.

Read More