Discover how the quality team at Continental Diamond Tool ensures high standards through every phase, from pre-production to final inspections.

Read MoreLearn how CDT’s vitrified bond grinding wheels deliver precision, customization, and efficiency across industries. Trusted for high-performance manufacturing since 1973.

Read MoreOptimize your grinding process with expert tips on speeds, feeds, Q-prime, and advanced bond technology to boost efficiency in precision manufacturing.

Read MoreLearn how to diagnose and fix common surface pattern problems in precision grinding with expert insights from CDT's Senior Product Engineer, Paul Christy.

Read MoreDiscover CDT's four essential bond systems for superabrasive grinding wheels: Resin, Metal, Vitrified, and Electroplated. Optimize operations with expert insights from Jeff Wirth.

Read MoreIn episode 5 of The Grinding Chronicles, CDT Product Manager Troy Giacherio shares top techniques for dressing Vitrified CBN grinding wheels using Diamond Rotary Dressers. Learn how to use key parameters such as velocity ratio and overlap ratio to enhance dressing and truing operations in precision grinding.

Read MoreUncover the secrets behind top-notch results in grinding and machining of tough steels and metals. Discover the unique properties of Cubic Boron Nitride (CBN) and Aluminum Oxide and learn how to choose the right abrasive for optimal efficiency and precision.

Read MoreWe explore the transformative impact of custom superabrasive grinding products on the ceramics industry, highlighting the benefits they offer and the cutting-edge technologies driving these innovations.

Read MoreDiscover 7 reasons why CBN grinding wheels are your next game changer >

Read MoreAt CDT, our Vitrified products generally serve two distinctly different markets, Vitrified CBN and Vitrified Diamond. Learn about what makes a Vitrified wheel and the capabilities Vitrified has.

Read MoreWhat is a Vitrified Superabrasive Grinding Wheel and what are the benefits of using one? In this blog, you’ll learn who should switch to Vitrified >

Read MoreIn part 3 of this 3-part blog series, we explore the advantages and limitations of the Vitrified Grinding Wheel in various grinding applications.

Read MoreWe reviewed the materials of the Vitrified Grinding Wheel development in part 1 of this blog series, now we will discuss the bond. Learn more >

Read MoreThe vitrified bond grinding wheel first appeared 150 years ago, and continues to become ever more valuable. Learn more about the evolution >

Read MoreCustomers report significant improvements to the grinding process and cost savings with CDT’s latest generation of Vitrified Diamond grinding wheels. Learn more »

Read MoreEach type of bond, vitrified, resin, metal or plated, has distinct performance characteristics. Learn about the choice between diamond and CBN as it relates to vitrified grinding wheels.

Read MoreWhen high material removal and dimensional control is a concern, a vitrified wheel should be the first choice. Learn more benefits of a vitrified wheel >

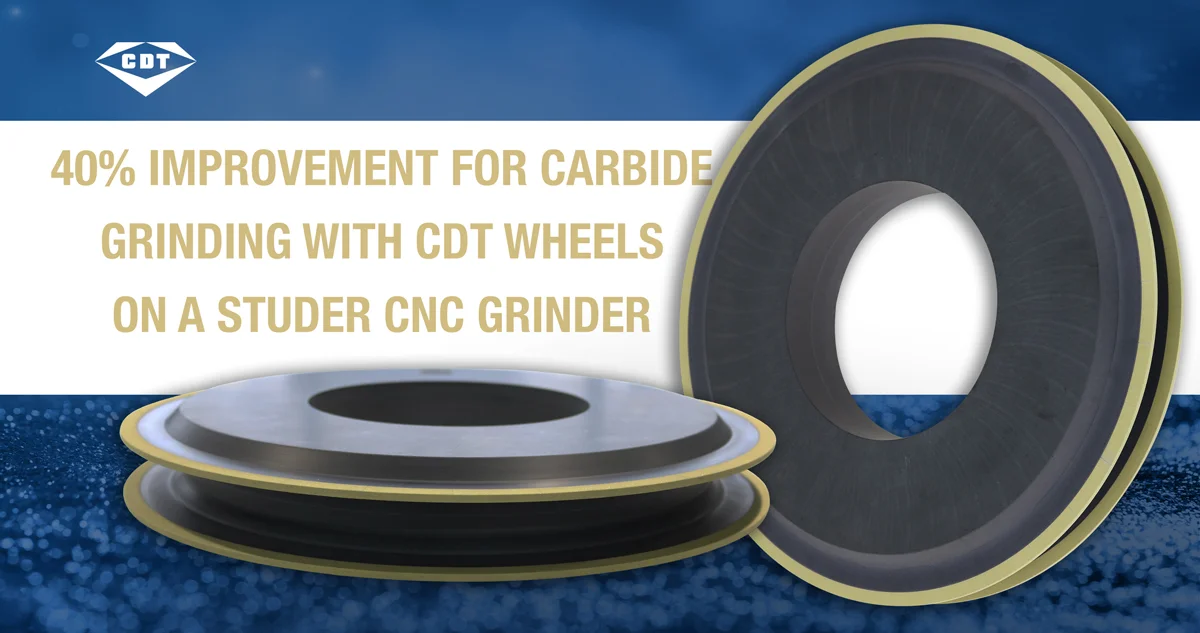

Read MoreCheck out how our engineers were able to add value to carbide grinding using Studer CNC grinders with a custom vitrified grinding wheel by CDT.

Look for these qualities when choosing a diamond wheel supplier.

Read MoreLearn about the benefits of the various types of abrasives used in the oil and gas industry.

Read More