Our grinding lab gives us the opportunity to work with customers to develop grinding processes that are specific to their materials, equipment, and applications. Learn more >

Read MoreSuperabrasive grinding wheels last longer, grind faster, cut cleaner, leave a better finish and create a sharper edge. The real question is—Why not?

Read MoreCheck out this guide on how to order custom grinding wheels that are a perfect fit for your operations.

Read MoreHere’s a rundown of industries that are known to benefit from the toughness and precision of custom CBN and diamond grinding solutions through CDT. Check it out >

Read MoreWe discuss six common grinding problems and offer solutions to help you solve some of your most challenging grinding issues. Check it out >

Read MoreA lot of customers ask if we keep stock inventory on the shelf. Check out the answer in this article >

Read MoreWe look at the 'total cost' of a custom superabrasive grinding wheel from CDT, and detail the advantages superabrasives have over conventional grinding products. Check it out >

Read MoreWith CDT’s recent investment in CNC automation through robotics, they are seeing benefits to quality, speed, and employee satisfaction. Check out what this new technology means for CDT customers and employees >

Read MoreIf a customer needs it, CDT makes it happen. Check out just how we accomplish this with our custom superabrasive products in our latest blog article >

Read MoreThe mechanics of producing aircraft to safely transport people in such harsh conditions, however, is particularly challenging. The solution? Plated CBN grinding wheels.

Read MoreAt CDT, our Vitrified products generally serve two distinctly different markets, Vitrified CBN and Vitrified Diamond. Learn about what makes a Vitrified wheel and the capabilities Vitrified has.

Read MoreContinental Diamond Tool now offers a new generation plated product available on carbide, aluminum, copper, or steel substrate bodies.

Read MoreWhat is a Vitrified Superabrasive Grinding Wheel and what are the benefits of using one? In this blog, you’ll learn who should switch to Vitrified >

Read MoreIn part 3 of this 3-part blog series, we explore the advantages and limitations of the Vitrified Grinding Wheel in various grinding applications.

Read MoreWe reviewed the materials of the Vitrified Grinding Wheel development in part 1 of this blog series, now we will discuss the bond. Learn more >

Read MoreThe vitrified bond grinding wheel first appeared 150 years ago, and continues to become ever more valuable. Learn more about the evolution >

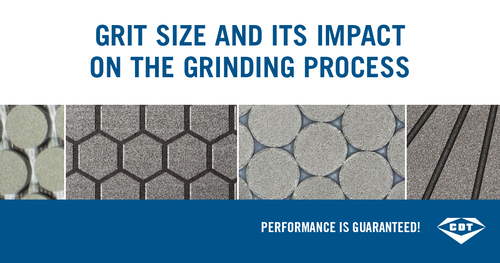

Read MoreGrit size only approximately correlates to surface finish: machine condition and the type of workpiece make a big difference. Learn more >

Read MoreCDT’s grinding lab for research and development will expedite innovation in the grinding industry and reduce costs for customers.

Read MoreQuality and precision are essential in complex, face grinding operations. CDT has fixed abrasive grinding wheels for fine grinding, double-disk grinding, blanchard grinding and more.

Read MoreFind the perfect rotary diamond dresser for your application by considering these 5 factors. Continental Diamond Tool Limited offers decades of expertise and free consultations for customized solutions >

Read More