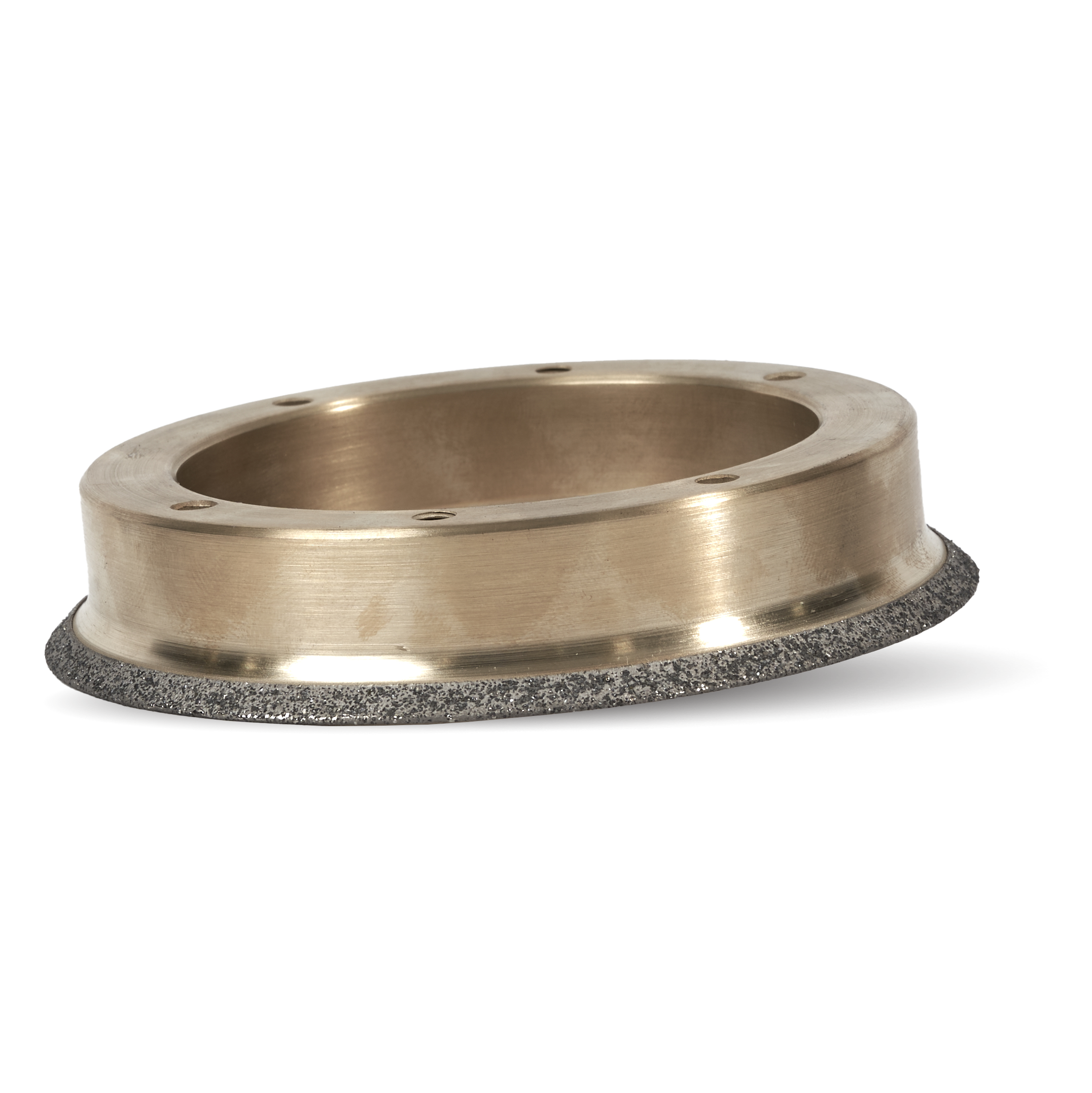

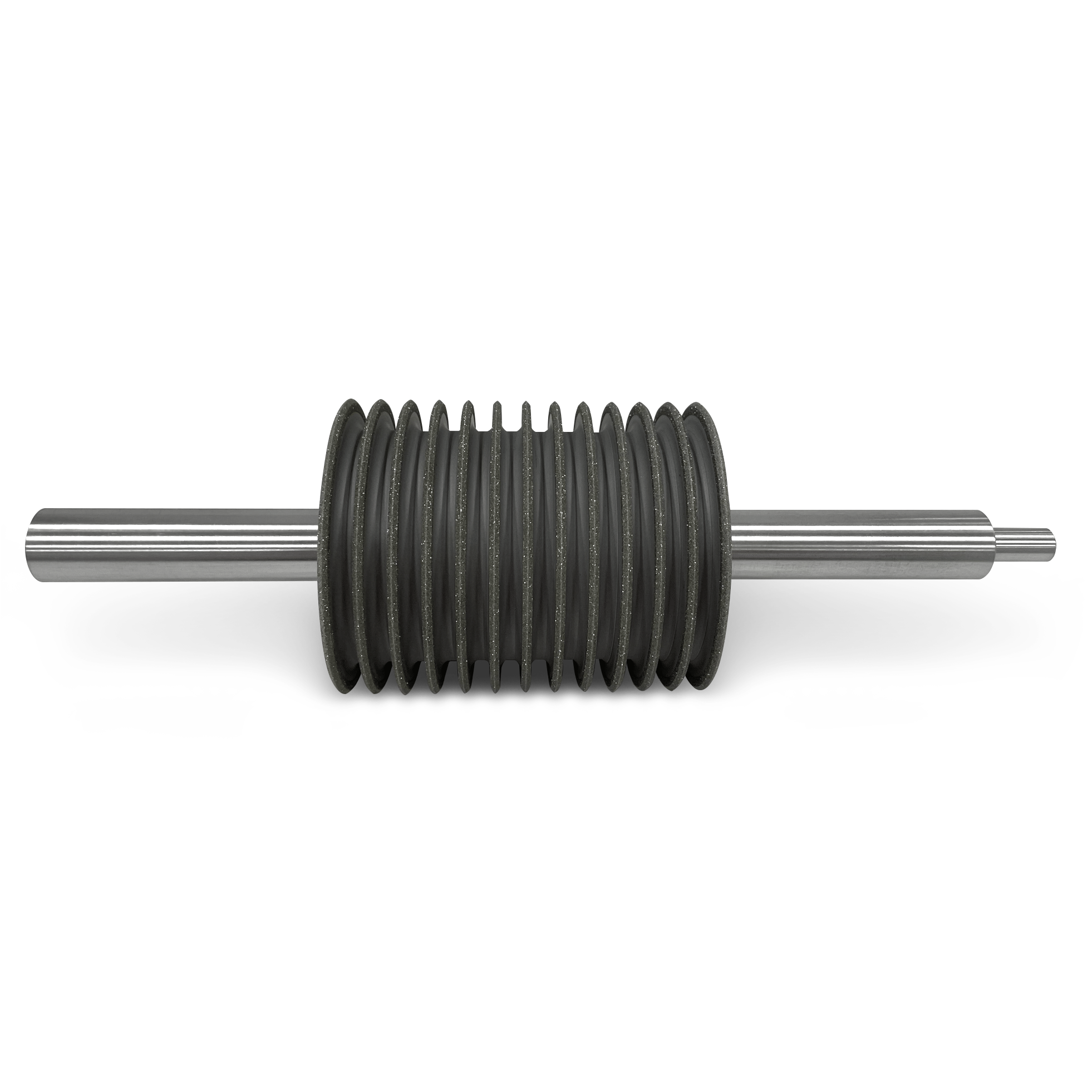

ELECTROPLATED DIAMOND GRINDING WHEELS

For Fast, Free Cutting and HIGH REMOVAL RATES

• Free Cutting Action = Fast Cycle Times

• Reusable with Strip And Replate

• No Dressing

ABOUT PLATING

Grinding wheels and tools produced by plating have a single layer of abrasive bonded to the surface by a strong, durable coating of nickel. Unlike metal and resin bonded tools — where the abrasives are mixed and held together in metal or resin — plated products have the best abrasive protrusion. Plated products are also reusable through CDT’s strip and replate services — with potential savings of 40% over new plated products.

FOR YOUR COST SAVINGS AND CONVENIENCE 🇺🇸 🇬🇧 MOST OF OUR ELECTROPLATED DIAMOND GRINDING WHEELS CAN BE MANUFACTURED and shipped from North America or Europe.

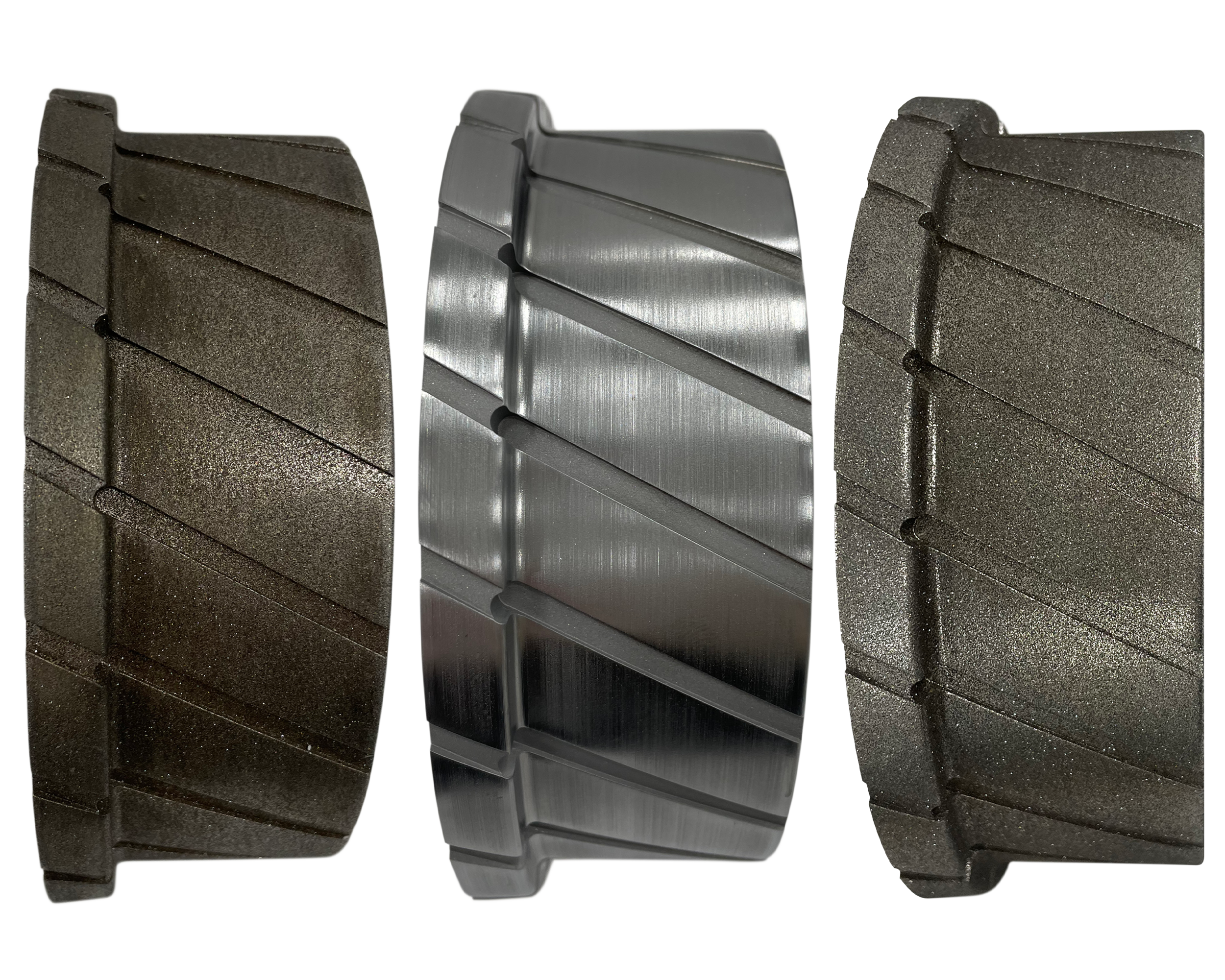

BEFORE, STRIPPED, AND AFTER REPLATING

Recondition Your Plated Wheels

Strip and replate Program

We work closely with our customers to develop customized, cost-effective programs to strip and replate their tools. Our strip technology removes the remaining abrasive without damaging the surface finish of the core, returning the tool to "like new" condition after replating.

Abrasive Utilization

Every wheel CDT produces including an electroplated grinding wheel is customized to our client’s specific needs. Below is a list of common applications for our plated products, but we thrive on finding unique solutions to increase performance and reduce waste. Contact us for a quote.

By INDUSTRY

Common industry

applications include:

Metal Cutting Tools

Woodworking Tools

Glass and Ceramic

Cutoff

PDC Cutters

Centerless

Cylindrical

Surface

Creep Feed

Roll Grinding

Saw & Knife Sharpening

PCD Grinding

Surgical Tool Blade Sharpening

Saw Blades

By Materials

Diamond grinding wheels:

Cemented carbide

Glass

Ceramics

Fiberglass

Plastics

Composites

Abrasives

Stone

Electronic components

CBN grinding wheels:

High-speed tool steels

Die steel

Hardened carbon steels

Hardened stainless steels

Alloy steels

Aerospace alloys

Abrasion-resistant ferrous materials

By MACHINE

CDT frequently supplies plated grinding wheels for machines by the following original equipment manufacturers (OEMs):

Campbell

DMG Mori

Gleason

Haas

LapMaster

Makino

Star

Download Product Sheet

FREQUENTLY ASKED QUESTIONS

-

Electroplated diamond tools contribute to superior performance and cost-effectiveness. The reasons include

• Consistent distribution of abrasive particles

• Strong bond between abrasive and substrate

• Versatility in applying various abrasive materials

• Ability to customize thickness precisely

-

Electroplated diamond grinding wheels are suitable for materials like:

• Die steel

• Hardened carbon steels

• Hardened stainless steels

• Alloy steels

• Aerospace alloys

-

At CDT, we use strip technology to safely remove the worn-down abrasive without damaging the wheel's core. We remove old abrasive with a chemical solution, and a new layer is applied through electroplating. The wheel is then re-balanced to perform for a long run.

-

Electroplated CBN grinding wheels excel in applications requiring complex shapes or geometries, such as:

• Metal cutting tools

• Saw and knife sharpening

• PCD grinding

• Surgical tool blade sharpening

• Aerospace engine components

-

At CDT, our electroplated diamond tools withstand heavy use, provide consistent performance, and require less frequent reconditioning than other wheel types. This results in long-term cost savings of up to 40%. Request a free quote now.