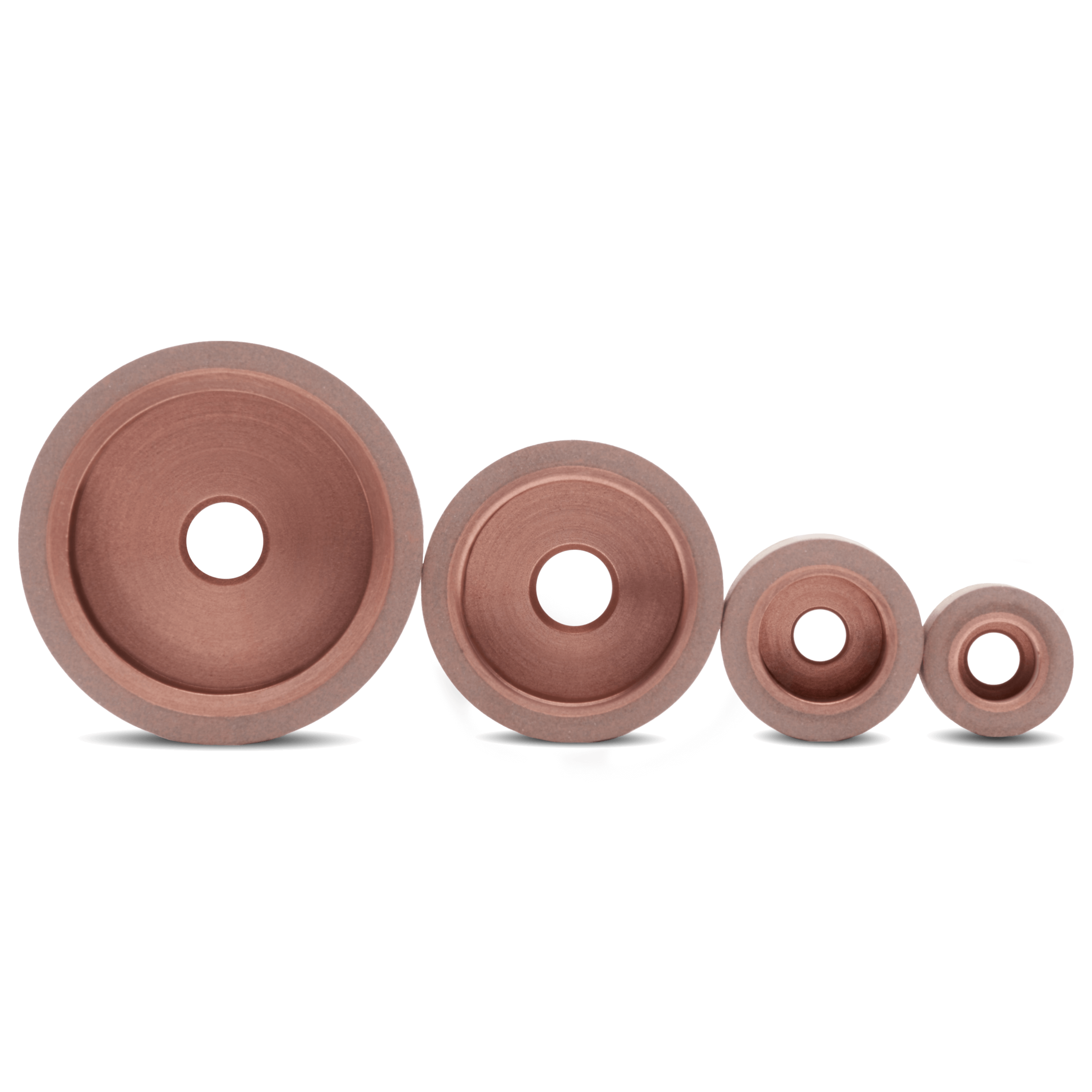

RESIN BOND Diamond and CBN Grinding Wheels

For High Performance Grinding with Versatile Capabilities

• Convenient And Easy to Use/Flexible

• Custom Formulas For Your Application

• Low Cost Superabrasive

ABOUT RESIN BOND DIAMOND WHEELS

Since 1978, CDT has been perfecting its Resin Bond Diamond and CBN wheels. Diamond or CBN particles are embedded in phenolic resin or copper (along with other fillers), and combined in a hot-press process to create a variety of useful shapes and sizes. These are then cured and machined into tools that offer improved cutting action, productivity, and longer life for your industry or custom needs.

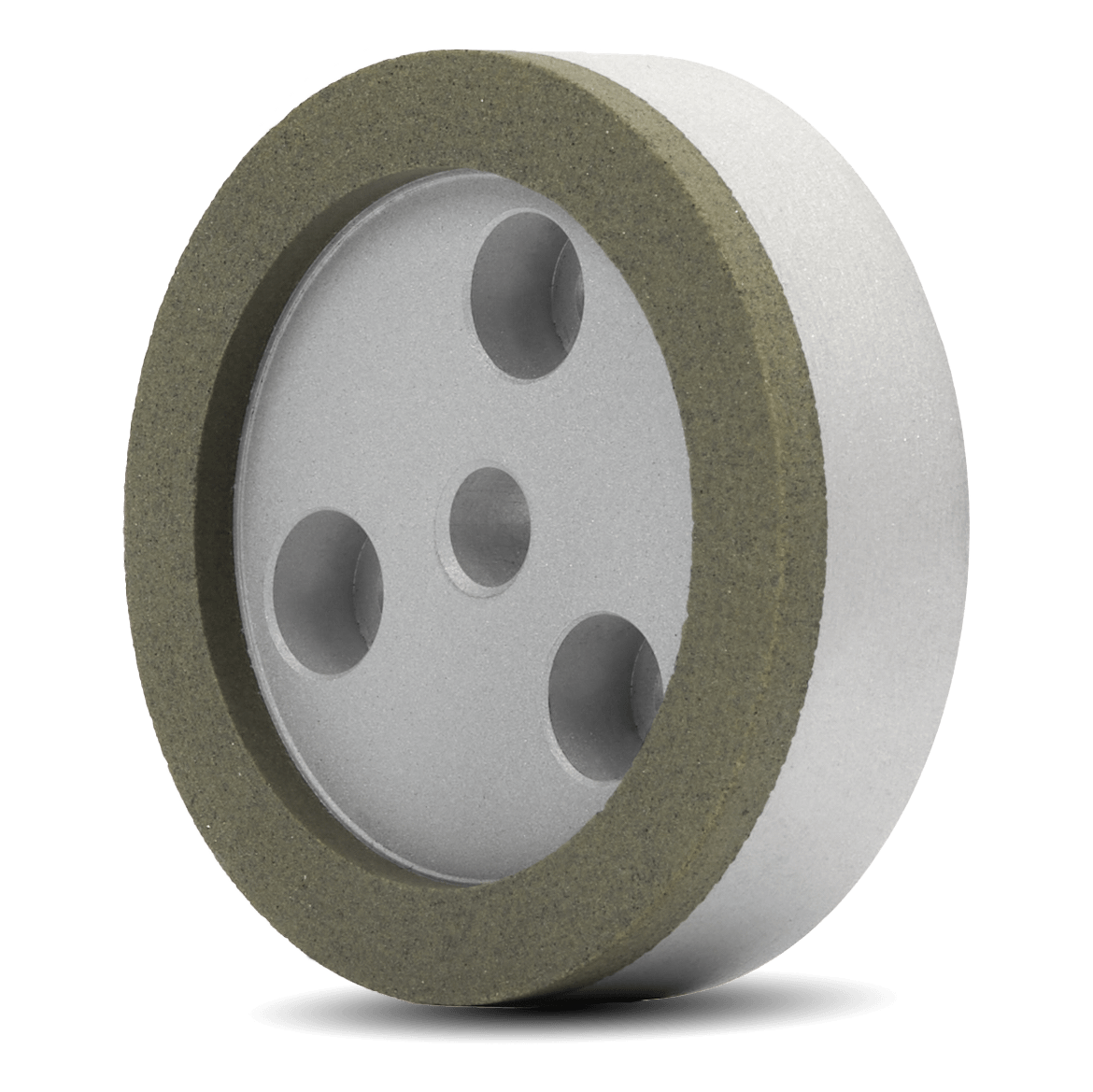

In 2017, CDT introduced its EVO Hybrid Series of grinding wheels and tools specifically for the Cutting Tool industry. Using advanced bond technology, this line takes the best of Metal Bond and Resin Bond to create a grinding wheel with ‘next level’ efficiency and free cutting action.

Whether you need polishing, sharpening, light or heavy grinding, our Resin Bond diamond grinding wheels and EVO Hybrid Bond products will meet or exceed your expectations. Each tool is custom designed to your unique specifications. We stand behind our craftsmanship, backed by our Performance Guarantee.

From Resin to Hybrid BOND

EVO Advanced Bond Technology

DESIGNED EXCLUSIVELY FOR THE CUTTING TOOL INDUSTRY

Benefits include > Free cutting action > Good form holding > Stable grinding > Cool cutting body that draws heat from the tool > High feed rate > Improved wheel life > Less wheel dressing

Flute from solid, regrind, gash and end work, and relief.

Abrasive Utilization

Every wheel CDT produces is customized to our client’s specific needs. Below is a list of common applications for Resin Bond Grinding Wheels, but we thrive at finding unique solutions aimed at increasing performance and reducing waste. Contact us for a quote.

By iNDUSTRY

Common industry applications include:

Metal Cutting Tools

Woodworking

Glass & Ceramics

Profile Grinding

PDC Cutters

Centerless

Cylindrical

Surface

Creep Feed

Cutoff

Roll Grinding

Tool & Cutter

Saw & Knife Sharpening

PCD Grinding

Surgical Tool Blade Sharpening

By Materials

We recommend resin bond grinding wheels for:

Tungsten Carbide

Ceramics

Stainless Steel

HS Steel

Titanium Nitride

Zirconia/Aluminum Oxide

Ferrites

Powdered Metals

Sintered Silicon Carbide

Titanium Graphite Composite

By MACHINE

CDT frequently supplies resin bond diamond grinding wheels for machines by the following original equipment manufacturers:

ANCA

Rollomatic

Star

Studer

USACH

Vollmer

Walter

View Product Sheet

FREQUENTLY ASKED QUESTIONS

-

Each CDT grinding wheel is tailored to meet the distinct grinding parameters of our customers. Pricing for these custom products depends on the specific requirements of the grinding wheel, which is dictated by your unique application and process. To request a free quote, please contact our dedicated sales team at 800-443-6629. Obtain quick, accurate, and competitive pricing today.

-

CDT is happy to guide you on using its products:

• Mount the resin bond diamond grinding wheel onto the machine's spindle following the manufacturer's instructions.

• Use a dressing tool to expose fresh abrasive grains and ensure the wheel's concentricity and shape accuracy if needed.

• Operate the grinding machine at the recommended speed and RPM (rotations per minute).

• Apply consistent and appropriate pressure to the workpiece during grinding.

• If the grinding process generates too much heat, use water or a coolant to keep the workpiece and the wheel cool.

Need more information? Ask an expert. We are happy to talk through your particular problem or set up a time to visit your facility for in-person training on installation and use.

-

CDT is ISO Certified and offers a Performance Guarantee on all of its products. We stand by the high-quality standards and commitment offered to our clients. For specific warranty questions, contact your CDT representative.

Please feel free to call 800-443-6629, or email us with any questions.

-

Yes, absolutely. CDT prioritizes the safety of every user hence, all the products come with safety information to use the grinding wheel. Here are some of the safety guidelines that you must follow:

• Always handle and store wheels with care.

• Visually inspect all the wheels before mounting to check for potential damage.

• Ensure that the operating speed is within the established limit and does not exceed the wheel's speed rating.

• Verify that the mounting flanges have the same diameter and are correctly positioned.

• Utilize mounting blotters if they are provided with the wheels.

See our Safety Guide for Grinding Wheel Users for more details.

-

CDT prioritizes the safety of every user hence, all the products come with safety information to use the grinding wheel. Here are some of the safety rules that you must follow:

• Always handle and store wheels with care.

• Visually inspect all the wheels before mounting to check for potential damage.

• Ensure that the operating speed is within the established limit and does not exceed the wheel's speed rating.

• Verify that the mounting flanges have the same diameter and are correctly positioned.

• Utilize mounting blotters if they are provided with the wheels.

See our Safety Guide for Grinding Wheel Users for the complete set of recommendations.