CBN AND DIAMOND

Grinding Wheels and Tools

Precision CBN and Diamond Grinding Wheels

THE WORLD’S HARDEST DIAMOND TOOL AND ABRASIVES FOR INDUSTRIES’ TOUGHEST APPLICATIONS

Achieve precise, high-quality grinding with custom diamond and CBN wheels from Continental Diamond Tool. Ideal for hard materials like iron and steel alloys, our grinding wheels are designed for precision and durability. Superabrasive grinding wheels excel in delivering the best removal rates and longest wheel life for the most demanding, advanced grinding applications.

TYPES OF SUPERABRASIVES

Natural Diamond

Synthetic or Manmade Diamond

Cubic Boron Nitride (CBN)

SUPERABRASIVE BONDs

From grinding hardened steels to ultra-hard ceramics, diamond and cbn grinding wheels offer exceptional durability and accuracy. Each bond type has its own, unique characteristics and benefits.

Click on a category for more information.

DIAMOND GRINDING WHEELS FEATURES

» Custom designed and manufactured to your needs and specifications

» Process optimization through:

– Grain type

– Porosity or filler selection

– Tailored bond systems

» Diameters, operating speeds, and granular size vary by product and application. Contact our team for details.

APPLICATIONS

Superabrasive grinding wheels are indispensable in many industries where high precision, exceptional hardness, and extended tool life are critical for achieving the desired results:

Aerospace & Military

Automotive

Ceramics

Cutting Tools

Electronics

Fiberglass & Composites

Food Processing (Blade & Knife)

Medical/Dental

Oil & Gas

Optics & Precision

Paper & Cardboard

Power Generation

Tool & Die

Wire & Cable

Gems

Gears

Stone

Wood & Saw

WE OFFER DIAMOND AND CBN GRINDING Wheels IN ALL THE MOST COMMON BOND TYPES

Plated

Our Electroplated Diamond Grinding Wheels ensure efficient operation with:

● Free Cutting Action: Enjoy fast cycle times without sacrificing quality.

● Reusable: Our wheels can be stripped and replated, extending their life and reducing waste.

● Maintenance-Free: No dressing required, minimizing downtime and labor costs.

Vitrified

These wheels offer:

● Improved Cycle Times: Produce more in less time with our high-performance wheels.

● Lights Out Operation: Trust in the reliable performance for uninterrupted production.

● Efficient Heat Removal: Keep operations cool and consistent, protecting your parts and tools.

Resin

Our Resin Bond wheels provide:

● Ease of Use: Flexible and convenient for a variety of applications.

● Custom Formulas: Tailored to your specific requirements for unparalleled results.

● Cost-Effective: A low-cost option without compromising on quality.

Metal

Our Metal Bond tools offer:

● Long Life: Durable design for extended usability.

● Efficient Heat Dissipation: Keeps your operations cool, enhancing performance.

● Versatile Compatibility: Ideal for grinding glass, ceramics, carbide, and more.

Hybrid

Our Hybrid Bond products feature:

● Superior Wheel Life: Lasts longer with extended dressing intervals, saving time and money.

● Increased Productivity: Enhance your output while lowering process costs.

● Exceptional Precision: Achieve the highest feed rates without sacrificing accuracy.

CDT DIAMOND GRINDING TOOLS HAVE BEEN TRUSTED BY LEADING INDUSTRIES SINCE 1973

TECHNOLOGICAL SUPERIORITY AND PRECISION IN CBN/DIAMOND GRINDING WHEELS

Continental Diamond Tool has been at the forefront of precision tooling since 1973, employing the most cutting-edge technology and decades of expertise.

Global Reach

Take advantage of the convenience and cost benefits that come with production and shipping operations located in Europe and North America.

Custom Solutions

We specialize in crafting unique superabrasive products, ensuring that your tools are meticulously tailored to meet your specific requirements.

Performance Promise

We maintain the effectiveness, caliber, and output of our CBN and diamond precision tools. See our guarantee for more information.

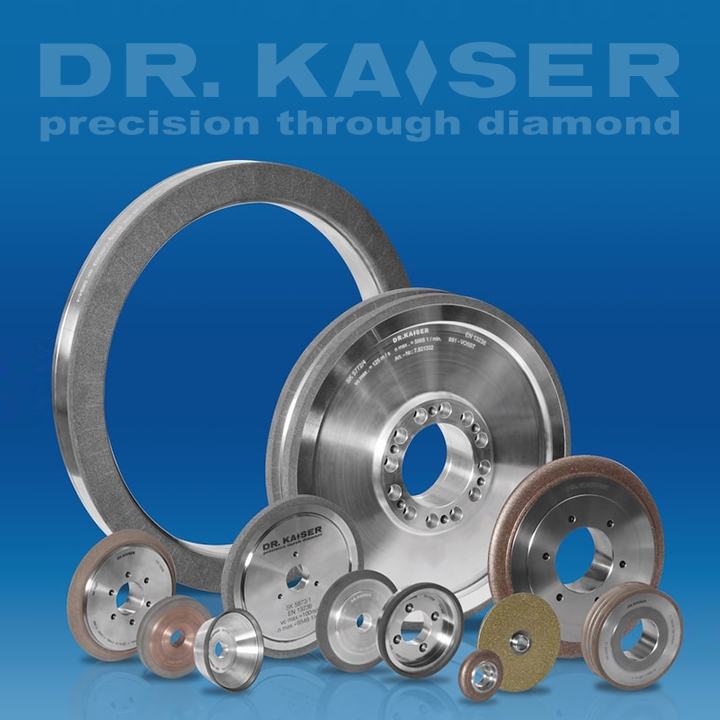

PartnerING WITH

DR. KAISER DIAMANTWERKZEUGE GmbH & Co. KG

CDT is the official representative for DR. KAISER products in North America, including their full line of diamond and cBN grinding wheels.

Contact us for more information.

Frequently Asked Questions

-

Absolutely. Our diamond grinding wheels are custom designed to suit specific applications. Our engineers customize the bonds, the geometries, and the process to make products that are suitable for a wide range of materials, including but not limited to, hardened steels, carbide, glass, ceramics, and composites. Our comprehensive selection of cbn and diamond abrasives means we can engineer the perfect formula for your application, whether you need aggressive material removal or a fine, polished finish.

-

While both diamond grinding tools and CBN (Cubic Boron Nitride) grinding wheels offer superior grinding capabilities for specific applications, the choice between them depends on the material you intend to work with. Diamond grinding wheels are the hardest and are ideal for grinding a wide variety of materials, especially non-ferrous materials and super-hard alloys. CBN wheels, on the other hand, are better suited for ferrous materials because it is nonreactive with those substances, unlike its diamond counterpart. Our team can help you engineer the right tool for your application, ensuring optimal performance and cost-efficiency.

-

As a premier manufacturer, we adhere to strict quality control procedures throughout the manufacturing process, from raw material selection to final inspection. Our tech diamond tools are made using state-of-the-art machinery and systems. Each tool is rigorously tested at multiple stages in the production process to ensure it meets our high standards for performance, durability, and safety. Our commitment to excellence has made us a trusted name in applied diamond tools, providing our clients with reliable and high-performing tools for all their grinding needs.

-

Yes, we specialize in providing custom solutions tailored to the unique needs of our customers. Whether you have a unique requirement for diamond grinding tools, need a custom size or bond type for your diamond grinding wheels, or require a specialized hybrid formula for a particular application, our team of experts is here to help. With our ability to customize products and our extensive experience in the industry, we can develop the perfect solution to meet your grinding challenges.